Product Description

SUMMARY OF EQUIPMENT TECHNICAL CHARACTERISTICS

Useful cutting dimension | 1,500 (transverse) x 3,000 (longitudinal) mm |

Laser Type | FIBER laser |

laser power | 1000 Watts |

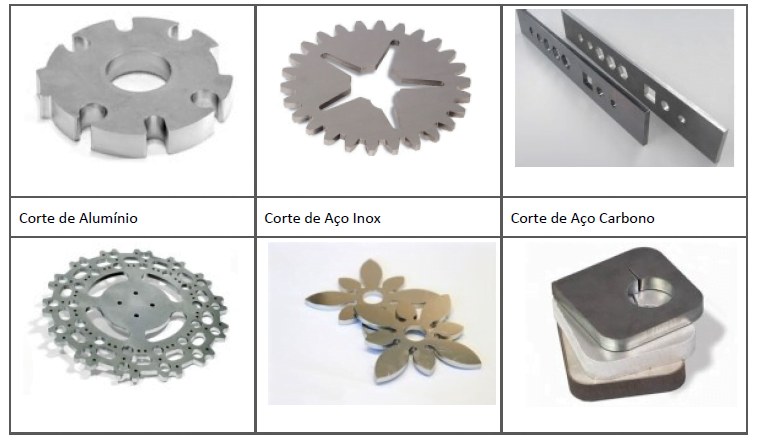

Maximum cutting thickness | Carbon steel – 12 mm Stainless Steel – 5 mm Aluminum – 3 mm

|

Max cutting speed | 26.000 mm / min |

Motorization | Servomotor AC – Brushless

|

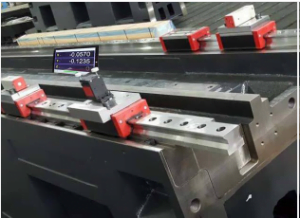

Traction System | high precision rack |

cutting head | Suspended type with anti-collision and dynamic focus (Australian technology) |

file format | PLT, DXF, AI, DST, etc. |

positioning accuracy | +/-0,02mm |

Repeatability | +/-0,03 mm |

Acceleration | 1,0 G |

Maximum Displacement Speed | 80 m/min |

used gases | Oxygen / Nitrogen / Compressed Air |

laser wavelength | 1064 nm |

Approximate machine weight | 3.000 Kg |

Food | 220 Vac / 380Vac Three Phase |

Total machine power (1000W)

| 12 KW |

WARRANTY: | 01 (ONE) YEAR |

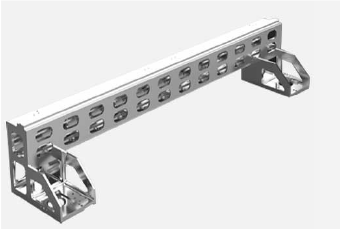

STRUCTURAL BASE:

The machine is built in the form of a gantry, with a welded steel frame. The lateral bases are made of steel, and all the support bases of the system are machined and ground to support the ground prismatic linear guides. After being welded, the structure is taken to an oven where we have temperatures in the order of ~650° C, for stress relief. This way, we avoid measurement errors at the different working temperatures of the equipment.

CROSS PORT:

It is made of cast aluminum, with aeronautical material of high hardness and resistance, ensuring lightness of the system, which makes the machine reach high accelerations with high speeds. On the supports of precision racks and linear guides, high-precision signage is made.

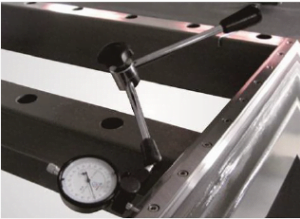

PRECISION AND LEVELING ADJUSTMENTS

The entire set undergoes rigorous precision and parallelism tests, with high-precision instruments, in order to guarantee positioning accuracy of 0.02mm.

EXAMPLES OF CUT MATERIALS